CASE STUDY #2

Initial problem

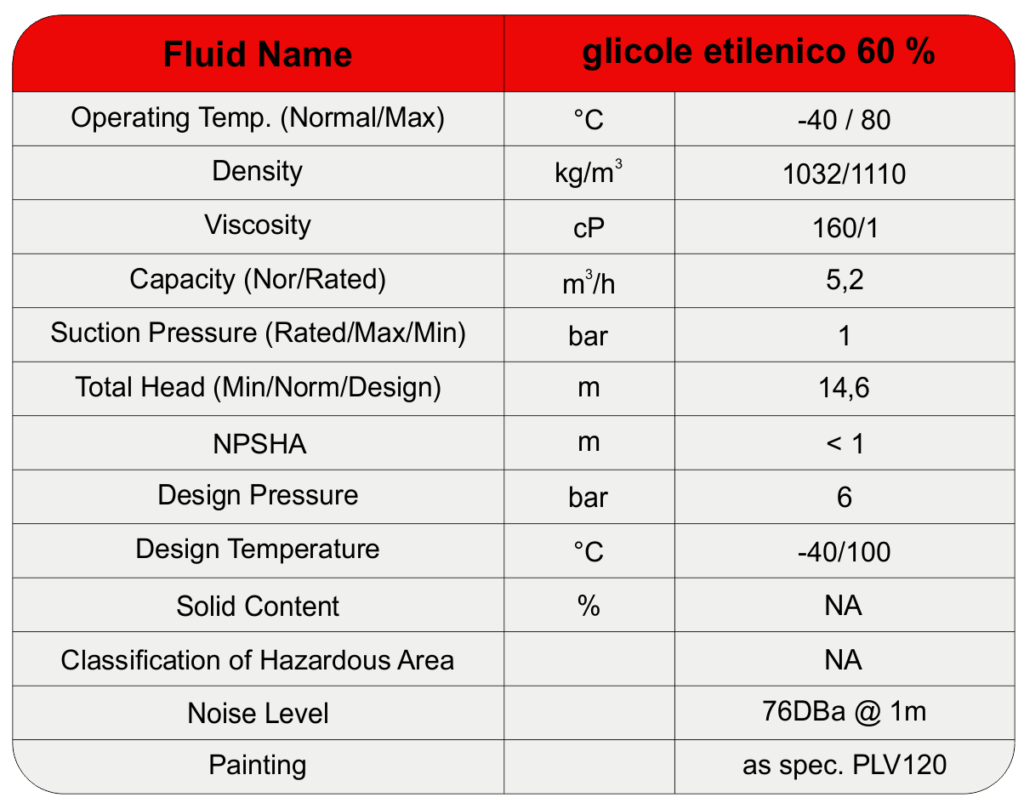

The customer is an international player in the field of cooling systems for railway use installed on the most common locomotives also used in Italy.

Each locomotive is equipped with approximately 3 – 4 inverters requiring cooling, which occurs via a standard system consisting of exchanger, fan and pump.

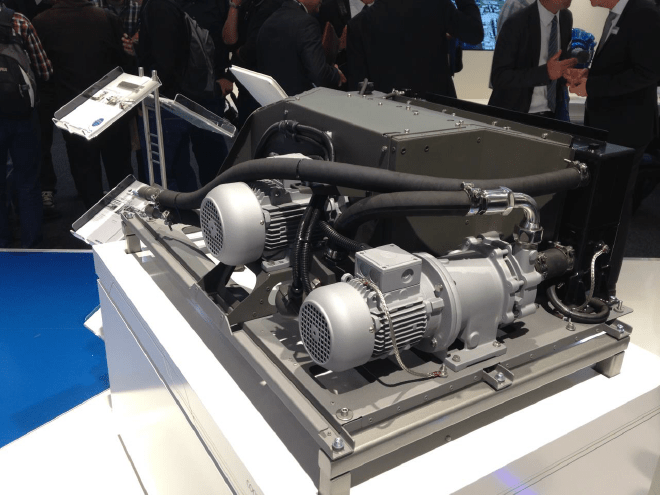

Until now, the only pump approved by *** for this service was a canned type pump of ***, the approval process is very complex since the pump must undergo a series of tests which ensure it is operational even during the limit conditions occurring on a train (vibrations, jolts, electromagnetic immersion and temperature changes).

M Pumps solution

We have proposed a cast iron magnetic drive centrifugal pump type CM-MAG-M2, a very economic pump but at the same time sturdily manufactured and therefore adequate to support that type of stresses. The tests performed have proven the full effectiveness and efficiency of our proposal. Introducing a magnetic drive pump has reduced the system electrical absorptions (as opposed to what is achievable with a canned pump) and therefore its overall efficiency has increased.

These comparative advantages are the prime reasons for clients to consider mag drive pumps against mechanical seal fitted pumps

M Pumps deliver world‐leading expertise in the design, application and manufacture of Magnetically Driven Pumps and associated equipment to API 685, ISO 2858, ANSI B73.3 and ASME for the Oil and Gas, Offshore, Petrochemical, Chemicals, Nuclear, Research Institutes, Pharmaceutical, Electronic and the General industry.